Cattle digest feed more thoroughly and the content of digestible substances such as protein and fat in cow manure is lower, mainly crude fiber. And due to complete digestion, the feces have fine texture, high water content, difficult to ventilate, and low fermentation temperature. Organic cow manure fertilizer has many benefits, here are some examples:

1. Improve the soil and make the land fertile. Since cow manure is a cold fertilizer and cattle are herbivorous, cow manure is low in protein and has more herbaceous fiber. It is suitable for application in fields with serious damage to the soil texture. Improve soil permeability and increase soil nutrition.

2. Increase the yield and quality of crops. Organic fertilizer is rich in various nutrients, such as crude protein, crude fat, and crude fiber. After decomposing organic fertilizer, it can provide energy and nutrients for soil microbial activities, promote microbial activities, and accelerate the decomposition of organic matter Produce active substances that can promote crop growth and improve the quality of agricultural products.

3. Improve the use of fertilizers. Organic fertilizers contain a large amount of nutrients, but the relative content is low and release is slow, while chemical fertilizers are rich in nutrients, high in composition, lower in composition, and fast release. The two are reasonable in application and complement each other. Organic acids produced by the decomposition of organic matter can also be used. They promote the dissolution of mineral nutrients in the soil and fertilizers.

To achieve these goals, what equipment is needed to produce organic fertilizer from cow manure?

(1) Measuring equipment. The measuring equipment must have a small scale of 20 kg or less, and a floor scale is generally used.

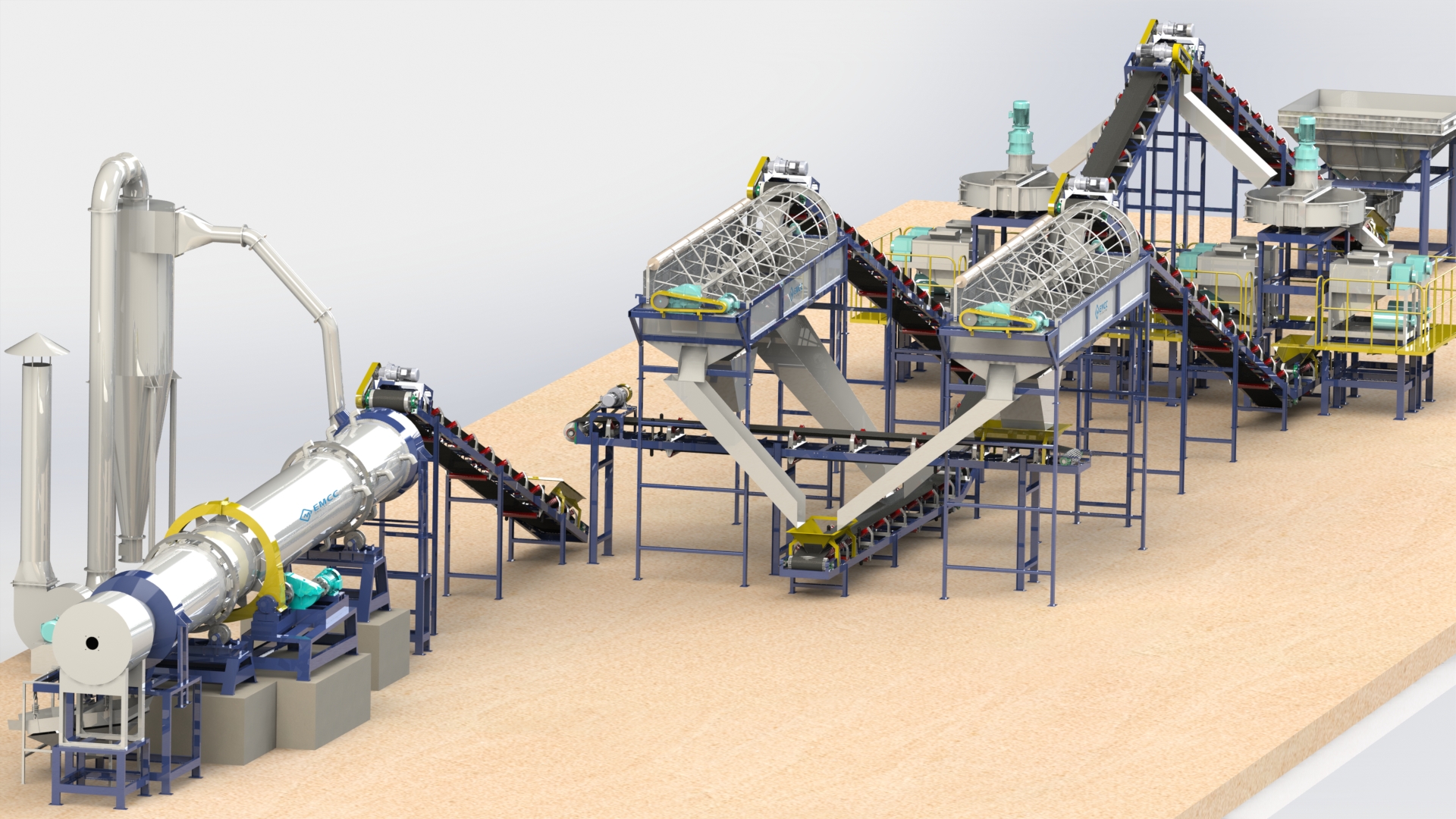

(2) The crushing equipment includes coarse crushing equipment and fine crushing equipment. The coarse crushing equipment is mainly used for crushing before classifying, and a semi-wet classifying crusher is used. Fine grinding equipment is mainly used for the second grinding after sorting to meet the fermentation particle size requirements. Generally, semi-wet crushers (fine crushing) are used.

(3) Sorting equipment is mainly used to remove plastic, glass, stone, metal and other non-alcoholic substances in livestock and poultry manure. The vibrating screen can be used to classify thick glass, stone and metal, and the magnetic metal can be classified. by a magnetic separator.

(4) The feeding equipment should send the materials to be processed from the storage area or the storage tank to the processing facility, which can use conveyor belts, bucket front loader, plate feeder, etc.

(5) The mixing equipment mainly uses twin screw mixers, disc mixers, etc. The supplied materials are transported uniformly and quantitatively to the fermentation equipment after mixing and shaking.

Therefore, the use of cow manure can be considered first to separate the dry substances from the wet ones by extrusion, and make full use of the high cellulose content in the dry matter to make an edible mushroom culture medium, such as the mushroom growing medium, and then growing the edible mushroom product the substrate is used for the production of organic fertilizers. Manure water can be fermented into biogas to produce biogas. The fermented residue can be composted and fermented to produce organic fertilizer. The water after fermentation can be used directly for crops, or it can be concentrated to make liquid organic fat.

Post time: Apr-08-2021