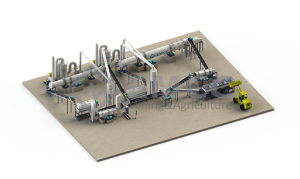

Disc Granulation Production Line

DISC GRANULATION PRODUCTION LINE

The disc granulation production line is characterized by its simpler operation, less material return, and higher granulation ratio.

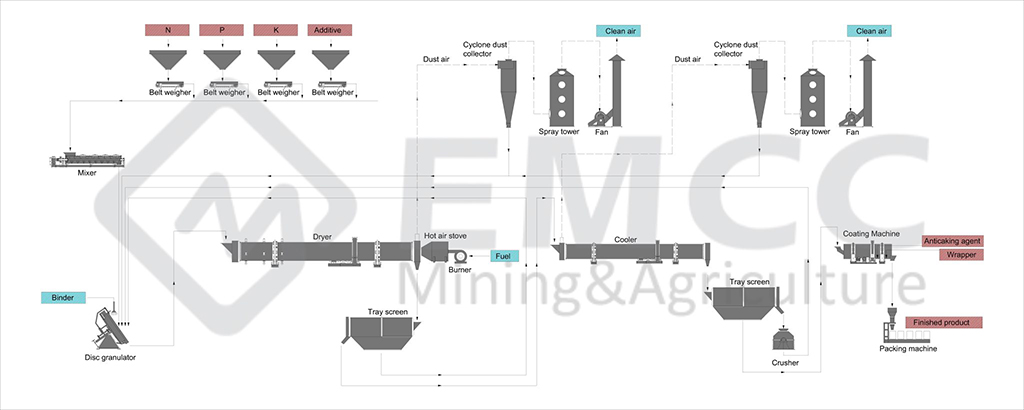

Generally, the process flow is: fertilizer raw materials batching–pretreatment & crushing– mixing–granulation–drying–cooling–screening & return–packaging–finished product.

RELATED EQUIPMENT

| Production Line Equipment | Supporting Equipment | Supporting Environmentally Friendly Dust Removal Equipment |

| Batching System | Crusher | Pulse Dust Collector |

| Disc Granulator | Mixer | Spray Tower |

| Drum Dryer | Elevator | Boiler |

| Drum Cooler | Belt conveyor | Combustion Device |

| Screening equipment | ||

| Coating machine | ||

| Packaging machine |

DISC GRANULATION PRODUCTION LINE IS AN IMPORTANT TECHNICAL MEANS OF WET GRANULATION PRODUCTION LINE

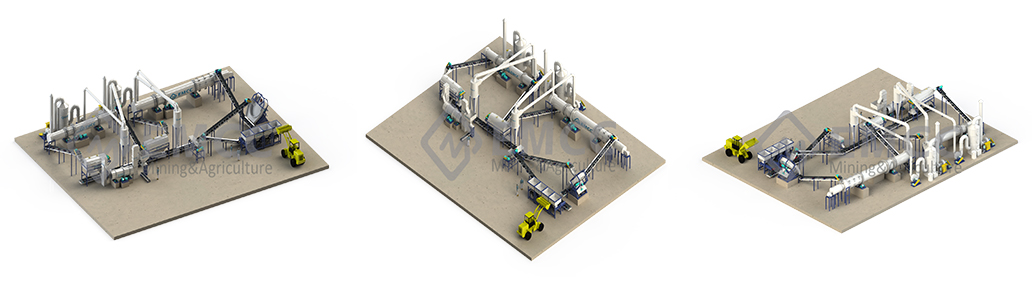

Disc granulation production line is the most commonly used technical means in fertiliser granulation production line, which is not only capable of producing compound fertiliser, but also pure organic fertiliser.

Disc granulation production line produces uniform particles, with good automatic grading ability, in the granulation at the same time can also add liquid, high granulation efficiency, generate fewer large particles, less return material. And disc granulation production line operation is intuitive and simple, easy to control, the formula can also be changed flexibly.

APPLICATIONS & MATERIALS

EMCC’s Disc Pelletizers can agglomerate everything from fine, dry feed materials, all the way to wet, sludge-like materials. Some of the most common applications for which pelletizer plants are built include:

| Chemical Powders | Coal fines | Filter / Centrifuge Cake | Pond tailings |

| Limestone / Gypsum | Cement / Lime Kiln Dust | Minerals and Ores | EAF Dust |

| Fertilizers | Flyash | Vibrating Sludges |