As the saying goes, “fertile water does not flow to strangers’ fields”. The “fertile water” here refers to human and animal fertilizers. Today, one of the most direct ways to turn chicken manure waste into treasure is to use the organic chicken manure fertilizer equipment production line. Using fresh chicken manure as raw material, through a series of processes, a natural organic chicken manure fertilizer is produced.

Chicken manure is a natural organic fertilizer commonly used by farmers. Due to their rich organic matter, humus and various elements necessary for the growth of fruit crops, they are widely used in the cultivation of fruits and vegetables. Analysis of the composition of organic chicken manure compost: Chicken manure contains organic matter 14.5%, nitrogen 0.30 ~ 0.45%, phosphorus 0.15 ~ 0.25%, potassium 0.10 ~ 0 ,fifteen%. It is a valuable resource that can be used by the planting industry as a source of fertilizer for the soil. Chicken manure has high organic matter and nutrient content, fine texture, high water content, slow decomposition, low calorific value, and is a late-acting fertilizer.

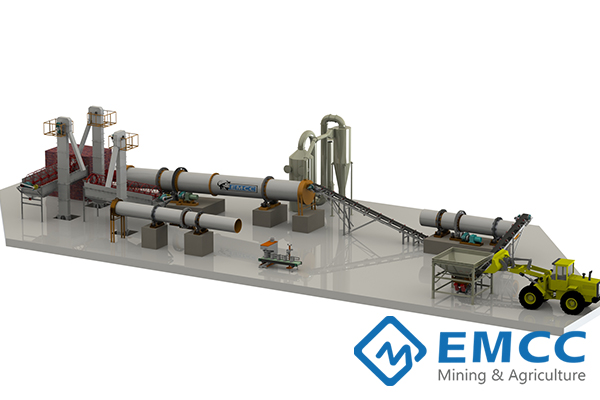

Chicken manure organic fertilizer equipment production line requires fermentation turner, organic fertilizer crusher, drum screening machine, horizontal mixer, disc granulator, rotary dryer, cooler, screening machine, coating machine, machine packaging, conveyor and other equipment. Organic fertilizer is produced by chicken manure organic fertilizer equipment production line, compact structure, advanced technology, harmless live bacteria preparations are used to treat livestock and poultry manure, biological fermentation is carried out carried out under the action of a variety of beneficial and organic microorganisms. The matter in it is fully decomposed to release nutrients. The formed high-temperature and biothermal fermentation process can kill germs, insect eggs, detoxify and deodorize, purify the environment, achieve safety, resource utilization and industrialization, low power consumption and stable product quality.

1.The organic chicken manure fertilizer equipment does not contain any chemical components. Due to the poor digestibility of chickens, only 25% of the nutrients can be consumed, while the remaining 75% of the nutrients in the feed is discharged with the manure, so the dry product contains nitrogen, phosphorus, potassium , organic matter, amino acids, proteins and other ingredients.

2. The main substance in chicken manure is organic matter, which increases the content of organic matter in the soil. Organic matter can improve the physical, chemical and biological properties of the soil, mature the soil and improve the fertility of the soil. The sayings from the rural areas of my country that “the land depends on manure and seedlings grow from manure” largely reflect the role of chicken manure in soil improvement.

3. Chicken manure not only adds a lot of organic colloids, but also decomposes a lot of organic matter into organic colloids with the help of microorganisms, which greatly increases the adsorption surface of the soil and produces a lot of sticky substances, which causes the soil particles to cement and The aggregate structure of the soil improves water retention, fertilizer retention and air permeability of the soil, as well as the ability to regulate soil temperature.

4. Chicken manure can also multiply microorganisms in the soil, especially many beneficial microorganisms, such as nitrogen-fixing bacteria, ammonifying bacteria, cellulose-decomposing bacteria, nitrifying bacteria, and so on. Chicken manure contains various active enzymes secreted by the digestive tract of animals and various enzymes produced by microorganisms. After these substances are applied to the soil, the enzyme activity of the soil can be greatly improved.

Chicken manure is used as an organic fertilizer in three ways: it is applied directly as an organic fertilizer after drying, or it is used as a raw material for the production of organic-inorganic compound fertilizer. After fermentation, it is used directly as an organic fertilizer or as a raw material for the production of organic fertilizers. During fermentation, it can be mixed with organic materials such as straw and distillery grains and then fermented. It can be fermented with compost, or it can be fermented with biogas and then mixed with other organic materials for composting, and then used directly as organic fertilizer or used as raw material for other organic fertilizers. After fermentation and drying, it is used directly as an organic fertilizer or as a raw material for the production of other organic fertilizers.

Post time: Apr-02-2021