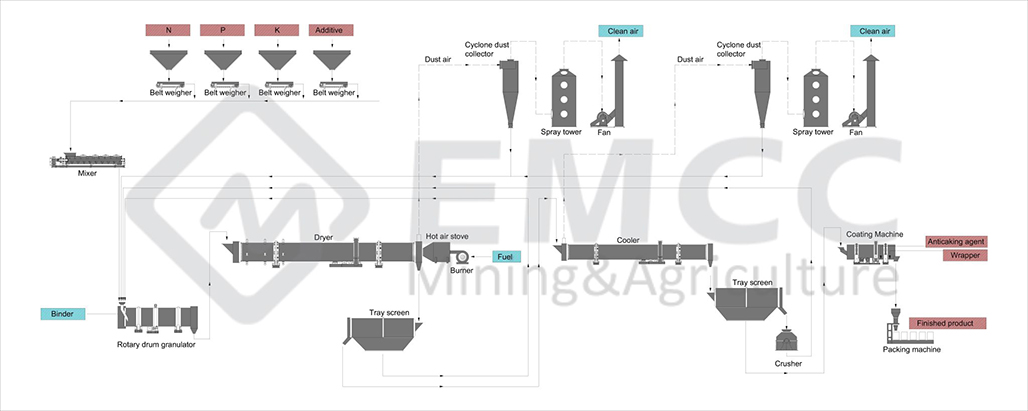

The rotary drum granulation production line is characterized by its large single unit production capacity and closed design. At the same time, it can use steam to add water and increase the temperature during the granulation process, so that it can reduce the energy consumption of the subsequent dryer process, to a certain extent.

Generally, the process flow is: fertilizer raw materials batching–pretreatment & crushing–mixing–granulation–drying–cooling–screening & return–packaging–finished product.

RELATED EQUIPMENT

| Production line equipment | Supporting equipment |

Supporting environmentally friendly dust removal equipment |

| Batching Systems | Crusher | Pulse Dust Collector |

| Drum Granulator | Mixer | Spray Tower |

| Drum Dryer | Elevator | Boiler |

| Drum Cooler | Belt conveyor | Combustion Device |

| Screening equipment | ||

| Coating machine | ||

| Packaging machine |

Wet granulation is the most widely used technology in fertilizer granulation production lines. It is widely accepted because of its wide applicable scope of raw materials, high production efficiency, good granular shape and high strength after drying.

The rotary drum granulation line is mainly used for the granulation of phosphorus compound fertilizers, such as monoammonium phosphate(MAP), diammonium phosphate(DAP), nitrogen-phosphorus-potassium compound fertilizers(NPK), heavy calcium superphosphate and many other products(TSSP). It is also used for ammonia granulation.

Meanwhile, rotary drum granulation line is also widely used in the production of organic and inorganic compound fertiliser.