-

The disc granulator can produce spherical pure organic fertilizer, organic-inorganic fertilizer, and bio-organic fertilizer; the particles are uniform, smooth, round, with high strength and good fluidity. The following EMCC will show you how to use the disc granulator and its parameters: 1. How t...Read more »

-

In the process of plant growth, there is no need for nutrients. There are large and micronutrient elements. At the same time, some plants also need some regulators to promote growth. What things contain nitrogen, phosphorus and potassium? Effects of phosphorus, potassium and nitrogen on plants ...Read more »

-

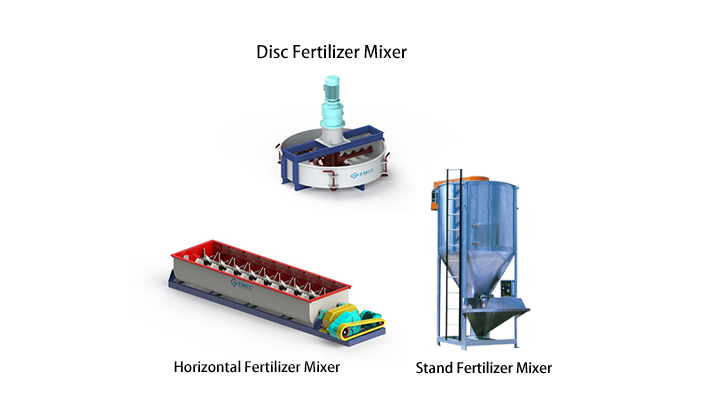

The vertical disc mixer is a special mixer for the fertilizer industry. It is a kind of mixing equipment specially used for organic fertilizer mixer produced by our company, with advanced design concept, compact machine and high practicability. The equipment consists of a stirring plate, a discha...Read more »

-

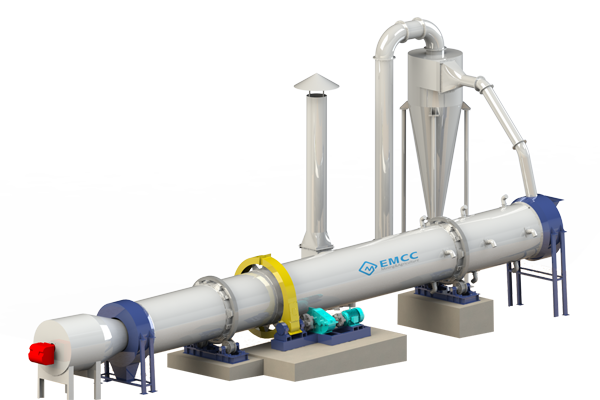

The organic fertilizer dryer is mainly used to dry granular materials within a certain humidity range. It is suitable for areas with relatively developed large, medium and small aquaculture. Depending on the requirements of the dried product, different heat sources can be used. Such as: gas gener...Read more »

-

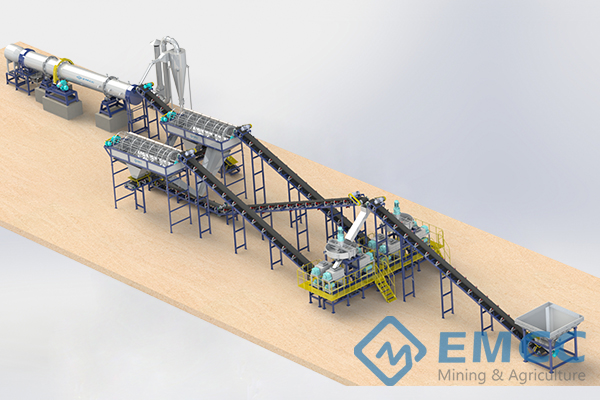

1. Pulverizing equipment (new semi-wet material pulverizer – vertical pulverizer and horizontal pulverizer, the internal structure has chain type and hammer type) 2. Mixing equipment (mixing mixers – including vertical mixers, horizontal mixers, double-shaft mixers, drum mixers, etc.)...Read more »

-

The drying-free compound fertilizer production line adopts the drying-free compound fertilizer extrusion granulation process: the solid material is agglomerated by increasing the pressure. Extrusion granulation is actually used for the production of crystalline products, powders, and organic raw ...Read more »

-

Preparation before test drive (1)The equipment parts are complete, the bolts are fastened, and the test conditions are met. (2)Check whether the clearance between the belt and the roller is appropriate: (3)Instruments and interlocking devices are complete, accurate, sensitive and reliable. (4) Ch...Read more »

-

Our company’s main products are 1-20 tons of organic fertilizer, bio-organic fertilizer, compound fertilizer, compound fertilizer production line, BB fertilizer complete equipment, drying and fermentation equipment for high-humidity materials such as chicken manure. It has created a precede...Read more »

-

The double shaft chain crusher is a professional crushing equipment for the crushing of large-volume raw materials. It is widely used in chemical, building materials, mining and other industries. High-strength wear-resistant carbide chain plates with synchronous speed are used in the crushing pro...Read more »

-

The organic fertilizer screening machine is a commonly used equipment in the production of organic fertilizer and compound fertilizer. It is mainly used for the separation of finished products and returned materials. Screening machine operation process: The roller device is installed obliquely o...Read more »

-

The hydraulic lift compost turner is used for the fermentation and turning of organic wastes such as livestock and poultry manure, sludge waste, sugar mill filter mud, slag cake and straw sawdust. The role of the hydraulic lift compost turner: 1. Stirring function in raw material conditioning. I...Read more »

-

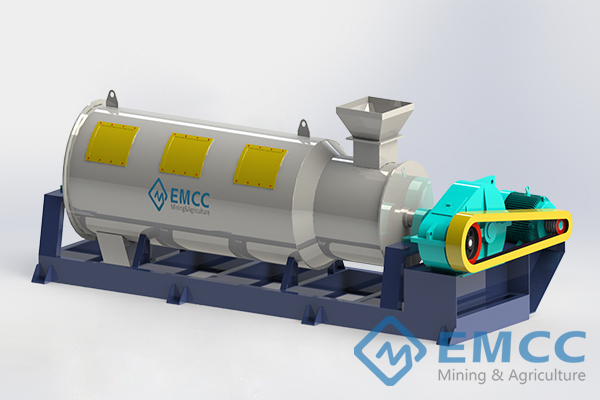

The stirring tooth granulator developed and produced by EMCC breaks through the conventional organic granulation technology and is suitable for organic fertilizer granulation. The granulation equipment greatly reduces the manufacturing cost. The new type of tooth stirring granulator is in short s...Read more »

-

For a long time, the abuse of chemical fertilizers has led to the decline of the quality of agricultural products. With the improvement of people’s living standards, new requirements have been put forward for the quality of food, and “pollution-free” has become the standard for ...Read more »

-

BB fertilizer is one of the most demanded types of agricultural fertilizers, and it is also one of the main fertilizers produced by fertilizer manufacturers. Our company absorbs domestic and foreign advanced technology to manufacture the BB fertilizer production line, which is of high quality an...Read more »

-

The organic fertilizer composter is a special fermentation equipment for producing bio-organic fertilizer. Compost Turner Maintenance and Maintenance Tips: (1) Daily maintenance and inspection (after working for 4 hours), check whether the connecting bolts, nuts and plugs are loose. (2) Check the...Read more »

-

In the production process of BB fertilizer equipment, various products can be produced by adjusting the ingredients and proportions of the formula, so BB fertilizer has become the best choice for balanced fertilization. How to give full play to the maximum efficiency of BB fertilizer machinery a...Read more »

-

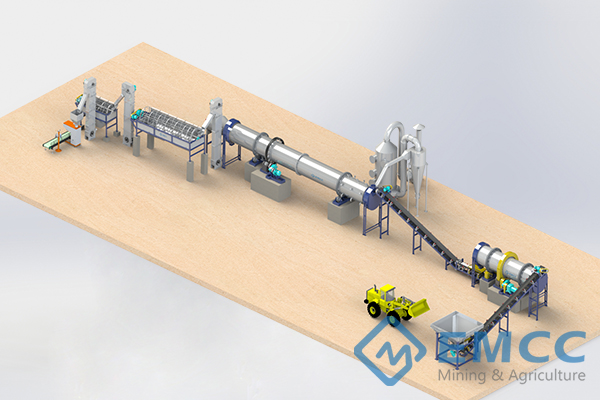

The complete organic fertilizer extrusion granulation production line consists of hopper and feeder, roller extrusion granulator, dryer, rotary screen, bucket elevator, belt conveyor, packaging machine and scrubber, etc. The equipment above is just a recommendation, we can also customize the pro...Read more »

-

1. Transport the treated poultry manure (cattle, sheep, chicken manure, etc.) directly to the raw material mixer; 2. Transported to the drum granulator, and steam (or water) is introduced at the same time. The material forms a rolling material bed by the friction generated by the rotation of the ...Read more »

-

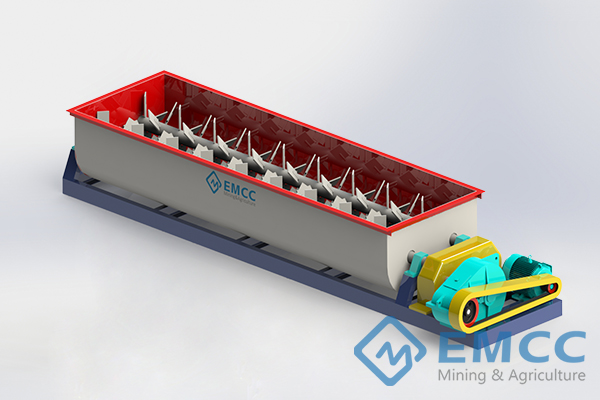

The double shaft fertilizer mixer is a new generation of mixing equipment developed by our company. This machine can fully mix the raw materials, and after the machine operation is completed, there will be no raw materials sticking to the inner wall of the machine. It is suitable for mixing organ...Read more »

-

Compound fertilizer is the fastest growing fertilizer variety in my country in recent years. In the production of powdery and granular phosphate fertilizers and compound fertilizers, the selected crusher is mainly used for the crushing of raw materials and large and large semi-finished products,...Read more »

-

Rotary Drum Screen is a commonly used organic fertilizer material screening equipment. When we use Rotary Drum Screen, the selection of the screen is very important. Then, how to choose the right screen? The screen is an important part of the screening machine, which is made of mulberry silk, me...Read more »

-

When producing organic fertilizers, we will come into contact with a variety of organic fertilizer raw materials. The properties of each material are different, and the mixers that need to be used are also different. In terms of the types of organic fertilizer mixers, they can be divided into hor...Read more »

-

The fertilizer packaging machine is an automatic high-tech product designed for the packaging of granular loose materials such as BB fertilizer, compound fertilizer, chemical raw materials, rice, feed, chemical fertilizer, etc. It consists of scale, feeder, weighing hopper, unloading hopper and a...Read more »

-

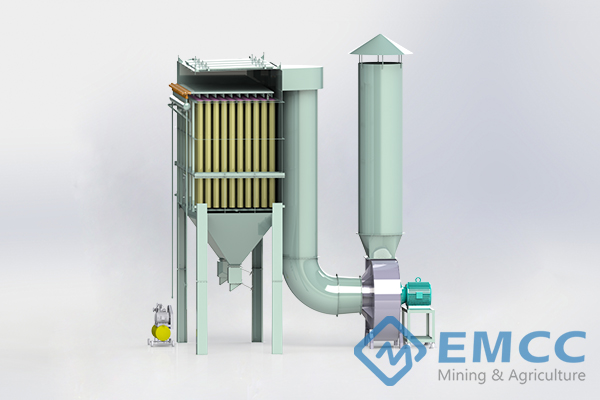

The filter type dust collector refers to the equipment that realizes the separation of gas and solid when the dust-containing flue gas pores pass through the filter layer, and the dust particles in the airflow are blocked and captured by the filter layer. The filter type dust removal device incl...Read more »

-

The lees dryer produced by EMCC operates at high temperature and relies on heat source to transmit, but there are many choices of heat source, such as natural gas, diesel oil, coal and so on. Organic fertilizer equipment distiller’s grain dryers often use coal and natural gas as heat sourc...Read more »

-

A detailed introduction to the types of organic fertilizers Carbonaceous materials are mainly derived from plants and/or animals and are applied to soil to provide plant nutrition as their main function. It is processed from biological materials, animal and plant wastes, and plant residues, which...Read more »

-

The intrinsic quality of organic fertilizer mainly depends on the fermentation part and the formulation of the product. The key factors in the fermentation part are: microorganisms, carbon-nitrogen ratio, carbon-phosphorus ratio, moisture, pH value, and ventilation control. If one factor is not w...Read more »

-

1. Intermediate temperature stage In the initial stage of compost production, the microorganisms in the compost are mainly medium temperature and aerobic species, and the most common are non-spore bacteria, spore bacteria and molds. They start the fermentation process of composting, vigorously re...Read more »

-

Compound fertilizer: refers to the fertilizer made by chemical method and (or) mixing method with at least two of the three nutrients of nitrogen, phosphorus and potassium. (At least two nutrients mentioned here are the basis of compound fertilizers. Otherwise, they are simple fertilizers or elem...Read more »

-

Cattle digest feed more thoroughly and the content of digestible substances such as protein and fat in cow manure is lower, mainly crude fiber. And due to complete digestion, the feces have fine texture, high water content, difficult to ventilate, and low fermentation temperature. Organic cow man...Read more »

-

As the saying goes, “fertile water does not flow to strangers’ fields”. The “fertile water” here refers to human and animal fertilizers. Today, one of the most direct ways to turn chicken manure waste into treasure is to use the organic chicken manure fertilizer equi...Read more »

-

The main actors in the composition of compound fertilizer production costs include raw material costs, variable manufacturing costs, and fixed manufacturing costs. First of all, let’s talk about the control of raw material costs: 1) Try to use cost-effective raw materials. 2) Reduce...Read more »

-

What are the specific functions of bio-organic fertilizer? Next, we will explain them one by one. 1. Provide crop nutrients Organic fertilizers contain a large amount of organic matter, which is slowly decomposed by microorganisms after being applied to the soil, and some of them will become si...Read more »

-

Organic fertilizer project has a short construction period, high return on investment, low market risk (organic fertilizer generally has a shelf life of at least 5 years), and short payback period (in case of busy farming, supply exceeds demand). The investment can be recovered in the year and pr...Read more »