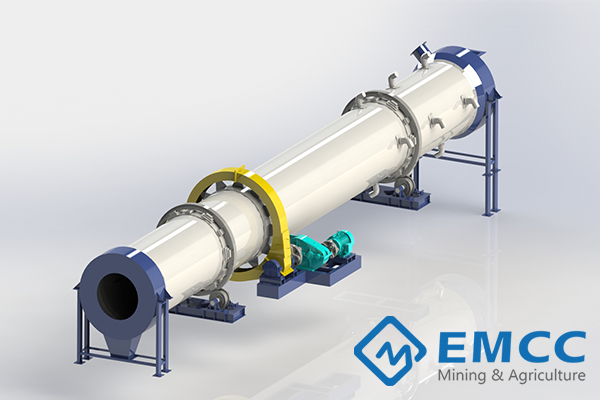

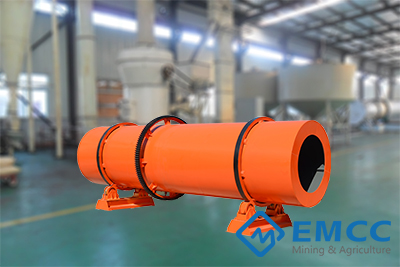

High Performance Fertilizer Product Line - Rotary Drum Fertilizer Granulator – Exceed

High Performance Fertilizer Product Line - Rotary Drum Fertilizer Granulator – Exceed Detail:

Rotary drum fertilizer granulator is one of the critical machines in compound fertilizer production line. It is applied to cold,hot granulation and quantity production of high,medium or low concentration compound blending fertilizer. The granulating method is rolling round fertilizer particles in wet granulation. With water or vapour added, the original fertilizer in rotary drum are blended uniformly and become humid, during this process, the fertilizer reacts and by way of the liquid environment and rotation in drum, the fertilizer particles squeeze each other and roll into fertilizer particles.The formed fertilizer particles are of 3-4mm.

Advantage

1.High fertilizer particles rolling rate about 70%, less returning fertilizer created,but can be regranulated.

2.Vapour or water adding improves fertilizer temperature and creates high quality fertilizer particles.

3.Engineering plastics are used for inner lining, no stick to liners,Anti-corrosion and thermal insulation.

4.Large granulating capacity,low enrgy consumption and low maintenance cost.

5.Flexible fertilizer particles diameter according to different formulation, processing procedure and raw materials.

6.Super quality steel materials,strict quality requirements and control.

7.Low noise,stable performance;rational structure like shoveling plates to clean drums.

Working principle

The raw materials enter into the rotary drum granulator by the belt conevyor. With the constant rotating of drum, the materials form a rolling bed, and moves along a certain path. Under the extrusion force produced, the materials agglomerate into small particles, which become the core, attaching the powder around to form the qualified spherical granules. The rotary drum is placed obliquely, the granules formed flow out through the outlet of the granulator. The shovelling plates inside the drum help granulating and cleaning

Technical Parameters

| Model | Inner diameter (mm) | Length (mm) | Working speed (r/min) | Capacity (t/h) | Angle (°) | Power (kw) |

| GL-1240 | 1200 | 4000 | 17 | 1-3 | 2-5 | 5.5 |

| GL-1560 | 1500 | 6000 | 11.5 | 3-5 | 2-5 | 11 |

| GL-1870 | 1800 | 7000 | 11.5 | 5-8 | 2-5 | 15 |

| GL-2080 | 2000 | 8000 | 11 | 8-15 | 2-5 | 18.5 |

| GL-3210 | 3200 | 10000 | 9.5 | 15-30 | 2-5 | 37 |

Product detail pictures:

Related Product Guide:

Global Superconducting Quantum Interference Devices Market Share | Organic Liquid Fertilizer Manufacturers

North American waterways are becoming saltier and more alkaline | Organic Liquid Fertilizer Manufacturers

Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for High Performance Fertilizer Product Line - Rotary Drum Fertilizer Granulator – Exceed, The product will supply to all over the world, such as: Indonesia , Mecca , Saudi Arabia , We have a dedicated and aggressive sales team, and many branches, catering to our main customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!